Converting $m^3/s$ to $kg/s$¶

To convert the obtained volumentric flow rate($m^3/s$) from rotameter into mass flow rate($kg/s$), density of the flow is required. If we know the density of the flow at any point on the flow path of rotameter then we can convert volumetric flow rate into mass flow rate. This can be stated in another way,

$$ \dot{q} = Av$$$$ \dot{m} = \rho Av$$

If we know the density of the flow then we can convert the volumetric flow rate obtained from rotameter into mass flow rate. To get the density of the flow, we need to know the pressure of the flow. Hence, If we use the pressure measuring device before rotameter then we can get the estimate of the density of the flow.

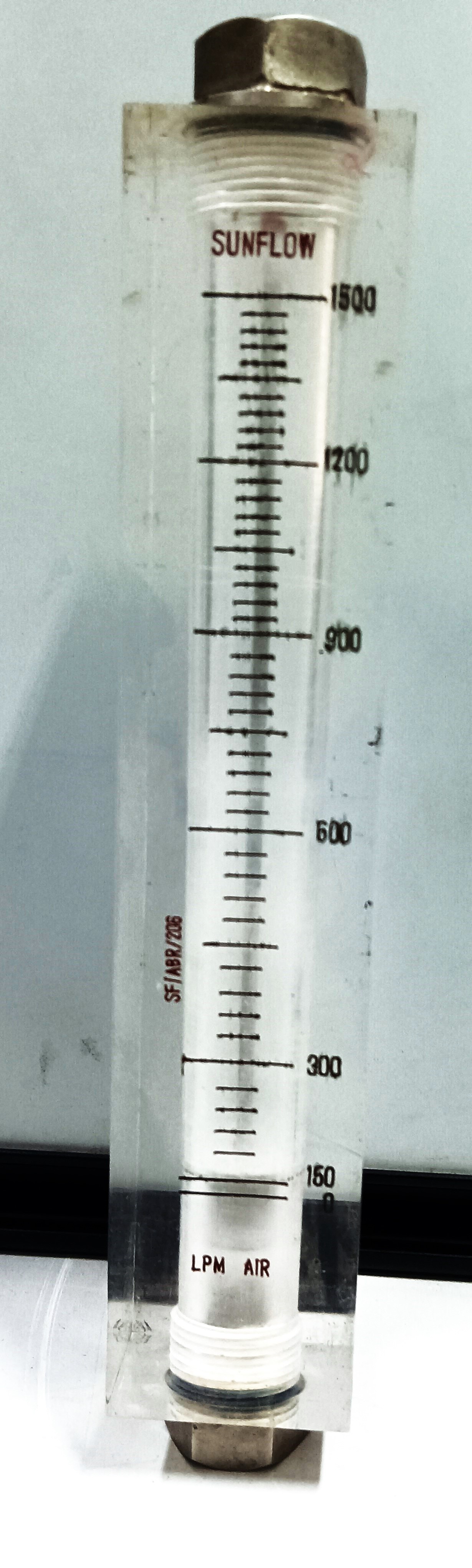

Rotameter with Pressure transducer attached before it

Above figure shows the setup of the rotameter, where pressure transducer (PT) is attached before rotameter. The pressure obtained from this PT will be indicative of the density of the flow. Hence using the rotameter LPM reading and PT reading in bars, we will be able to calculate mass flow rate in $kg/s$.

Use of ML¶

One way to convert the measured PT and LPM data into $kg/s$ is from theoretical approach. But then, we will also have to consider various losses of pipelines and connectors into account, whose values we don't know. But, we know this for sure that, with rotameter and PT value we can get mass flow rate. Hence, converting of the input values to output values was performed by ML-regression task. To perform ML, we first need the known value of mass flow rate and then characterize the rotameter setup using that. In short, we were required to calibrate the system. We used Alicat series mass flow controllers to supply known amount of mass flow rate $kg/s$ into the system and measure rotameter (LPM) and PT's (bar) value. Alicat mass flow controllers provide the mass flow rate in Standard Liters per Minute(SLPM) unit. Hence, the data shown below will showl SLPM as the unit of mass flow rate.

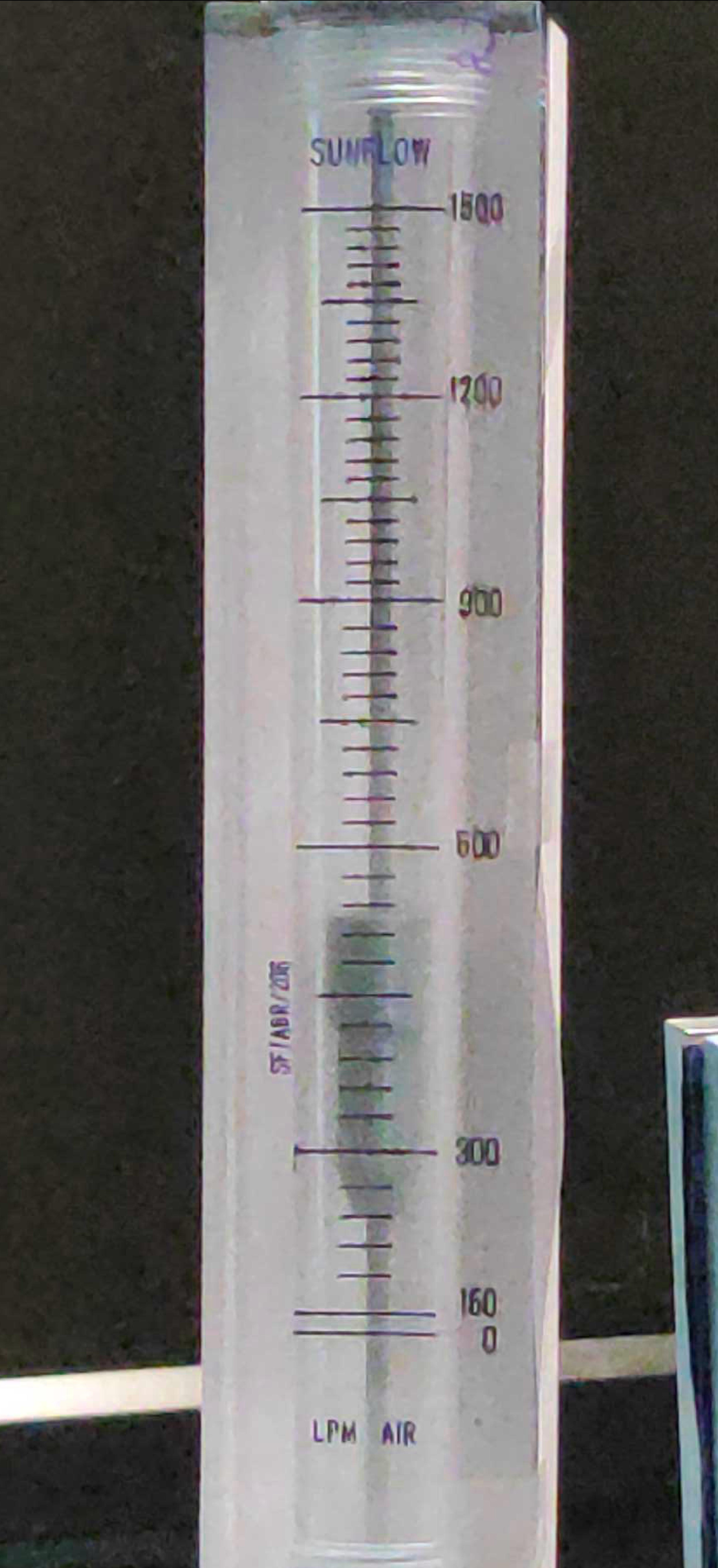

Reading of rotameter at one of the sample point

Below figure shows the plot of sample data collected during callibration of rotameter. It is observed that with increase in inlet pressure, the LPM reading of rotameter decreases for constant inlet SLPM. This is obvious, as we increase the inlet pressure, there will be increase in density of the flow, hence for a given inlet mass flow rate($\dot{m}$) the volumetric flow rate will reduce with increase in inlet flow density.